A high gross margin means the company retains a higher percentage of revenue from sales after subtracting the cost of manufacturing, which can be invested in operating costs and profit. By effectively managing cost of good sold (COGS), cost of good manufactured (COGM), you can optimize profit margins, identify areas for cost reduction, and make financially informed decisions. Let’s explore their concept, their calculation, and their significance in the article below. Direct materials, direct labor, manufacturing overhead, and adjustments for work-in-process (WIP) inventory. This figure represents the total cost of raw materials that were actually converted into products during the year.

How to Calculate the Cost of Goods Manufactured (COGM)?

This includes the wages, salaries, and benefits of those employees who work directly on the production line or in the workshop. With COGM, you can clearly see the total investment required to turn raw inputs into finished products. Book a free chat with one of our in-house manufacturing experts to determine the solution that’s best for you. Equipping oneself with knowledge and tools can transform the way a manufacturer approaches cost management and creates a thorough understanding of the financial implications of COGM. The company employs eight shop floor workers – they constitute the direct labor.

Cost of Goods Manufactured Formula

Think of it as taking inventory of all the ingredients in your manufacturing recipe. For a clearer idea of how the COGM formula works, let’s look at a hypothetical example. A financial professional will offer guidance based on the information provided and offer a no-obligation call to better understand your situation. Our goal is to deliver the most understandable and comprehensive explanations of financial topics using simple writing complemented by helpful graphics and animation videos. We follow strict ethical journalism practices, which includes presenting unbiased information and citing reliable, attributed resources. For information pertaining to the registration status of 11 Financial, please contact the state securities regulators for those states in which 11 Financial maintains a registration filing.

Components of Cost of Goods Manufactured

To calculate cost of goods manufactured, you first need to determine all your production costs and WIP inventory. In summary, COGM reflects the total cost of manufacturing goods – whether they were sold or not – while COGS represents the cost of only those goods that were sold to customers during a specific period. Cost of goods manufactured is the total cost incurred by a manufacturing company to manufacture products during a particular period.

Use this information to evaluate the cost and profitability of producing and selling a product and make cost management cost of goods manufactured and resource allocation decisions. Calculate the Cost of Goods Manufactured (COGM) to total your manufacturing cost. This precision influences several aspects such as setting prices for products, optimizing production processes, managing costs effectively, and controlling inventory levels. A high COGM suggests high manufacturing costs, which may imply ineffectiveness in the production process.

- Mattias is a content specialist with years of experience writing editorials, opinion pieces, and essays on a variety of topics.

- This tool is crucial for businesses that prefer a straightforward approach and may not be ready to invest in more complex ERP systems.

- By employing this method to determine goods manufactured COGM, it also establishes an essential framework for effectively monitoring COGM over time.

- The initial work in progress (WIP) inventory of a corporation consists of the value of goods still being produced.

- By following this calculation, you can determine the total cost incurred to manufacture goods during a specified period and gain valuable insights into your production expenses.

- In summary, COGM reflects the total cost of manufacturing goods – whether they were sold or not – while COGS represents the cost of only those goods that were sold to customers during a specific period.

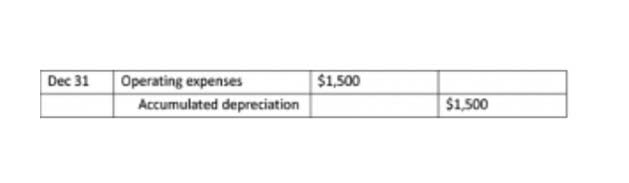

- Once all the calculations necessary to determine the Cost of Goods Manufactured for a year have been completed, the Cost of Goods Manufactured is estimated and then recorded in the Finished Goods Inventory account.

Double Your Sales Orders in 5 Steps

Cost of goods manufactured, or COGM, is the collective name for all costs incurred in creating a finished good that may be sold to consumers. The beginning WIP is what’s left unfinished from the previous period, while the ending WIP is what’s still in progress Accounting Periods and Methods after finished goods are accounted for. Most manufacturers aim to keep ending WIP low–it frees up cash, cuts taxes, and makes accounting a whole lot easier. Simply add your initial inventory, purchases, or manufacturing expenditures, and deduct the finishing inventory. This adjustment accounts for the change in the value of goods that are still in the production process and still need to be completed.

Would you prefer to work with a financial professional remotely or in-person?

The essence of the manufacturing process is encapsulated by production costs, which cover expenses for raw materials, direct labor, and manufacturing overhead. Every expenditure from acquiring raw material to remunerating assembly line workers plays a part in constituting the total manufacturing costs, with labor costs being key components. The total manufacturing costs can be computed by summing the expenses of direct materials, direct labor, and manufacturing overhead. Understanding how to calculate the cost of goods manufactured correctly is essential in accounting and finance as it helps businesses determine their gross profit margin for each product produced. It includes calculating all manufacturing-related expenses such as raw materials, labor wages, factory overhead expenses, depreciation on machinery or equipment used in production, etc. COGM is calculated by adding the beginning work in process inventory to the total manufacturing costs incurred during the period and subtracting the ending work in process inventory.

Understanding how to calculate the cost of goods manufactured is essential for tracking production costs accurately and effectively applying the cost of goods sold in formula manufacturing. It’s also important to understand the components of COGM, such as raw material costs, direct labor costs, and factory overhead, so that production costs can be managed more efficiently. Don’t hesitate to calculate it regularly and use technology to ease the process. To illustrate the cost of goods manufactured (COGM) calculation, let’s consider a manufacturer calculating its COGM for the fiscal year 2021. Then, add it to the purchases of raw materials made during the period and subtract it from the ending raw materials inventory, which is the number of raw materials on hand at the end of the period. The result is then added to the direct labor and manufacturing overhead costs incurred during the period to arrive at the COGM.

- Seamlessly integrate these solutions with popular ERP systems to enhance efficiency and accuracy across your operations.

- The total cost of those three expenses, or the cost of manufacturing, is $40 million.

- Additionally, understanding COGM helps businesses predict future market trends and adjust accordingly.

- In addition to the beginning and ending balances, it is necessary to account for raw materials and work-in-progress inventory.

- It’s essential for manufacturers to calculate COGM precisely because it directly affects pricing, cost control, profitability, and financial reporting.

Step 4. Prepare the Schedule of Cost of Goods Manufactured

Let’s dive into practical tips and solutions to make COGM calculations smoother and more accurate. Establishing robust relationships with suppliers plays a key role in preventing supply chain issues and maintaining a steady flow in the production process. Deskera ERP is a comprehensive system that allows you to maintain inventory, manage suppliers, and track supply chain activity in real time, as well as streamline a variety of other corporate operations. According to the accrual accounting matching principle, costs are recorded in the period in which the corresponding revenue was provided (and “earned”); for example, $0 in sales results in $0 in COGS. Like with most other financial computations, the calculation must be applied to a certain time period. Depending on the type of bookkeeping and payroll services organization you’re accounting for, this might change.